Many of our client companies that manufacture mattresses or other upholstered products have encountered moisture-related issues during storage or shipping, such as the formation of condensation inside the plastic film, as well as odours or stains on the covers.

This is not a minor detail. Proper management of residual moisture is essential to preserve product quality throughout the entire logistics cycle, right up to delivery to the final customer.

Direct experience from our clients confirms that simple, targeted solutions, such as the use of desiccants, can significantly reduce serious issues caused by moisture and condensation.

Residual moisture and risks in packed mattresses

The release of moisture from mattresses depends on several factors, including:

- Environmental conditions during storage or transport; temperature and relative humidity affect vapor release.

- The type and density of the foam, as memory foam, latex or polyurethane retain different amounts of residual water.

- Production curing and ventilation times; proper drying reduces residual moisture.

- Weight and size of the mattress, with larger mattresses retaining more water.

In practical terms, a single mattress can release 20–50 g of water, while a double mattress can reach 60–150 g of water, enough to cause issues in completely sealed packaging.

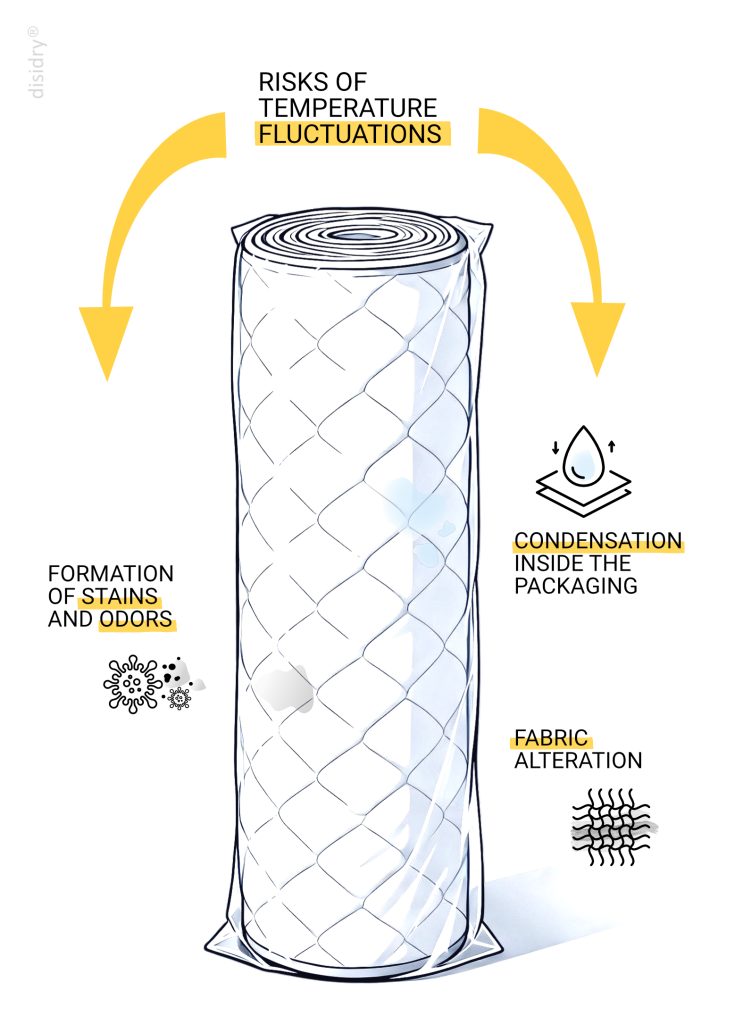

Factors contributing to condensation

During storage or transport, a sealed mattress may undergo temperature and relative humidity fluctuations. These changes affect the release and accumulation of residual water trapped inside the packaging, causing unwanted phenomena:

- Internal condensation: water vapor may condense on the mattress surface or inside the plastic film.

- Fabric or cover alteration: excess moisture can cause stains or localized deformation.

- Odours and mold: residual moisture and condensation promote odour formation or microbial growth.

The role of silica gel and desiccants in general

Many manufacturers address condensation and residual moisture issues by inserting, before sealing the packaging, silica gel packets or natural alternatives like clay desiccant bags to prevent potential problems.

The main characteristics of these desiccants are:

Stability and safety: they are completely inert and do not release liquids or unwanted substances.

Operational efficiency: they maintain a stable internal microclimate, absorbing residual moisture and preventing condensation, odours or stains.

Ease of placement: available in various sizes, allowing selection of the most suitable for the packaging.

The most commonly used bags are:

These sizes allow simple and uniform placement inside the packaging, ensuring good absorption capacity.

How many bags to use: practical guidelines

The quantities shown are indicative and come from our internal tests. They should always be evaluated considering factors such as external temperature, its variations over time, and storage duration, which can significantly affect results.

| Mattress type | Approx. weight | Residual moisture | Recommended bags silica gel 60 g clay 65 g |

| Single | 10 – 15 Kg | 0.2 – 0.4 % | 4 bags |

| Double | 20 – 35 Kg | 0.3 – 0.5 % | 6-8 bags |

Each company should validate the quantities with its own tests, considering weight, materials, and storage or shipping duration.

Desiccant bags are available in various sizes and formats to meet the specific needs of each production.

Integration into the production process

Anti-moisture bags are usually placed between the cover and protective film just before sealing, in a stable and discreet position. The main advantages include:

- Protection during seasonal peaks or long transports.

- Reduction of returns due to moisture-related defects.

- Uniformity in protection across different batches.

The same principle applies to sofas, armchairs, headboards, and other moisture-sensitive upholstered products that need to be transported or stored for medium or long periods.

Difference between silica gel and clay desiccant bags

The main difference is the type of desiccant agent contained in the bag. Silica gel packets use white silica gel crystals, a synthetic, chemically inert and stable material, with an absorption capacity around 20% of their own weight under standard conditions.

Packets with natural desiccant are filled with activated clay granules or montmorillonite, completely natural materials. The absorption capacity is comparable to silica gel under common operating conditions. Clay has some advantages: it is easier to dispose of, involves fewer shipping documentation issues for countries with restrictions on synthetic materials, and generally has a lower cost as it is a naturally extracted product.

Silica gel packets, while less cost-effective than clay, are required for specific applications or when explicitly indicated in technical specifications.

If you face moisture issues in your product packaging and need an effective solution, do not hesitate to contact us. We are here to help you find the best solution for your needs.

Not just product, but flexibility and service speed

In daily operations, we know how important it is to react quickly, listen to customer needs, and have an organization that allows flexibility. For this reason, we have built a service that goes beyond supply and follows the rhythms and needs of companies:

• Practically no MOQ, useful for quick tests or last-minute additions.

• Possibility to order small quantities online, without complex procedures.

• Fast shipping throughout Italy and abroad, to avoid slowing down production.

• Small batches, ready or customizable, opening only what is truly needed.

This combination of listening, responsiveness, and organization allows desiccant bags to be integrated into production and logistics processes with simplicity, continuity, and predictable timing.

Conclusions

We have examined the main causes that can lead to condensation and moisture inside mattress packaging, along with the most effective solutions to control them during storage and transport. Proper environmental management and the choice of the right desiccant significantly reduce the risk of stains, odours, and material degradation.

The good news is that these are problems that can be solved with simple, reliable tools. For technical details or to assess a specific situation, contact us at info@silica-gel.it.

All our desiccants are available for online purchase. Shipping is fast and usually processed within 24/48 hours (BD).